ULTRAFLOW V3

ACCURACY. REPEATABILITY. SPEED.

You just can’t test slow, with UltraFlow. The UltraFlow is LeakMaster’s latest mass flow leak testing innovation specifically designed for the air leak testing of exhaust or emission systems components. When your application requires extremely fast cycle times, we’re confident in saying UltraFlow is the fastest, most repeatable way to leak test exhaust components…period! Optional Ethernet/IP module for seamless integration with Allen Bradley EtherNet/IP or other compatible devices, eliminates I/O wiring, reduces start-up time and hardware cost. Provides ultimate control and the ability to capture valuable leak rate data for data collection systems, critical for today’s production environment.

MODERN CONNECTIVITY

PROVEN SOLUTIONS

TOTAL CONTROL

STILL THE FASTEST & PACKED WITH NEW CAPABILITIES

A LEAK TESTER DEVELOPED FOR ETHERNET/IP

NEW AND IMPROVED EtherNet/IP FEATURING “SLAVE MODE”

PROGRAMMABLE ELECTRONIC PRESSURE REGULATOR

DIGITAL MASS FLOW SENSOR WITH BROAD TESTING RANGE

NEW PRESSURE DECAY MODE FOR MICRO LEAK DETECTION

LED STATUS INDICATOR

DUAL ACCESS DOORS FOR FLEXIBLE MOUNTING

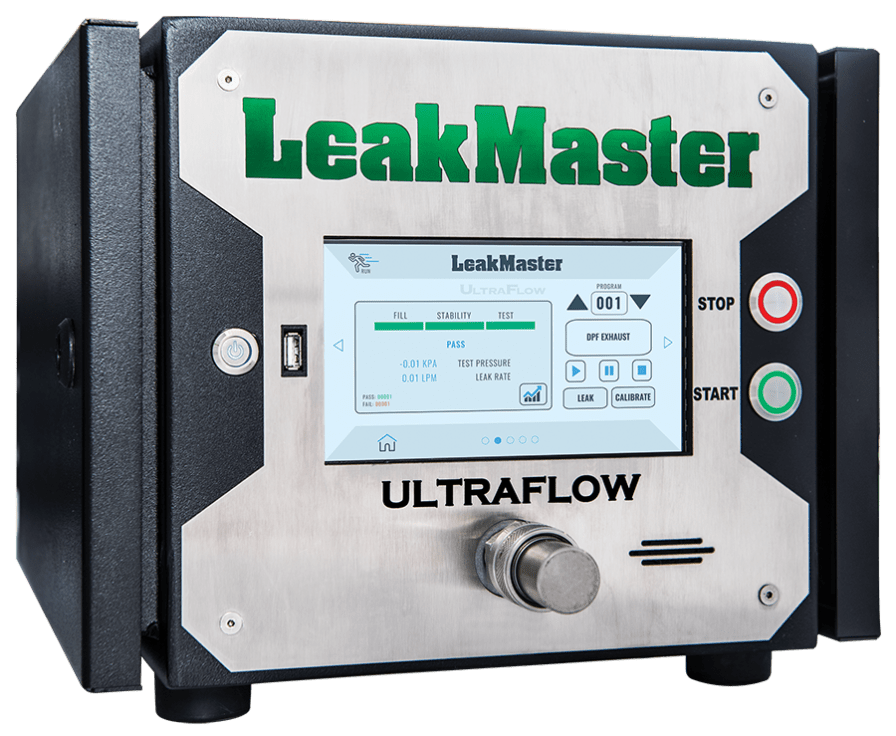

Simplicity in Operation

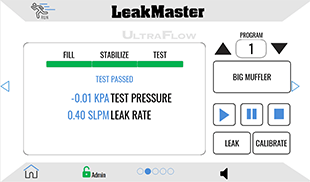

Run Screen

– The large, touchscreen display makes leak testing effortless.

– All pass/fail and in-process information are clearly displayed for easy viewing.

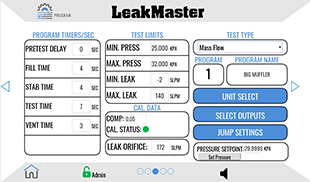

Setup Screen

– The easy to understand layout reduces set -up time, builds confidence, and eliminates confusion.

– The intuitive design gives unparalleled control, without multiple set-up screens.

– All leak timers and limits are clearly presented in their proper order.

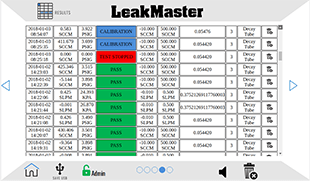

Results Screen

– Built-in data collection with auto save for proven, effective data collection; without hassle.

– The information is saved as a CSV file for viewing in Microsoft Excel or other text viewers.

Available Leak Test Modes

Leak testing is determining whether a product passes a specified leak limit. Leaks occur when a gas or liquid can escape a product caused by holes, cracks, insufficient seals, or permeable areas in a product due to defects in the manufacturing process. There are several different types of leak testing technologies available that can be implemented for specific applications. The chart below shows the different test types available for the Ultraflow V3 leak test instrument.

Pressure Decay

Vacuum Decay

Mass Flow

Differential Pressure

Occlusion

Metered Volume

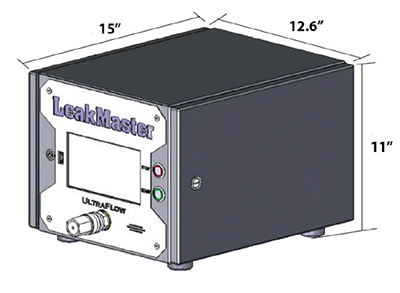

Technical Specifications

| Standard | Optional | |

|---|---|---|

| Programs Per Channel | 999 | |

| Number of Channels | 1 | |

| Mass Flow Sensor | 0-200 SLPM | 0-250 sccm, 0-750 sccm, 0-10 SLPM, 0-100 SLPM, 0-200 SLPM, 0-300 SLPM |

| Inputs | (16) 24VDC PNP | |

| Outputs | (16) 24VDC PNP | |

| Communications | Digital IO | Ethernet IP®, Profinet®, RS-232 |

| Data Collection | USB Flash, FTP | MasterCloud™ |

| Pressure Range | 0-15 PSIG | 0-30 PSIG |